Our services

-

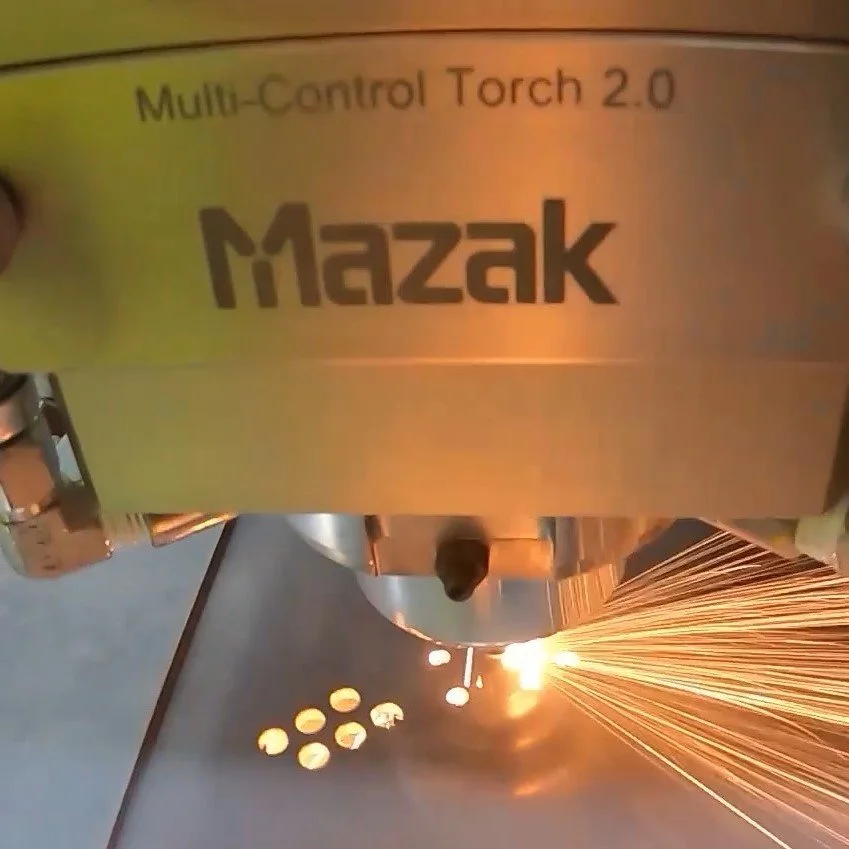

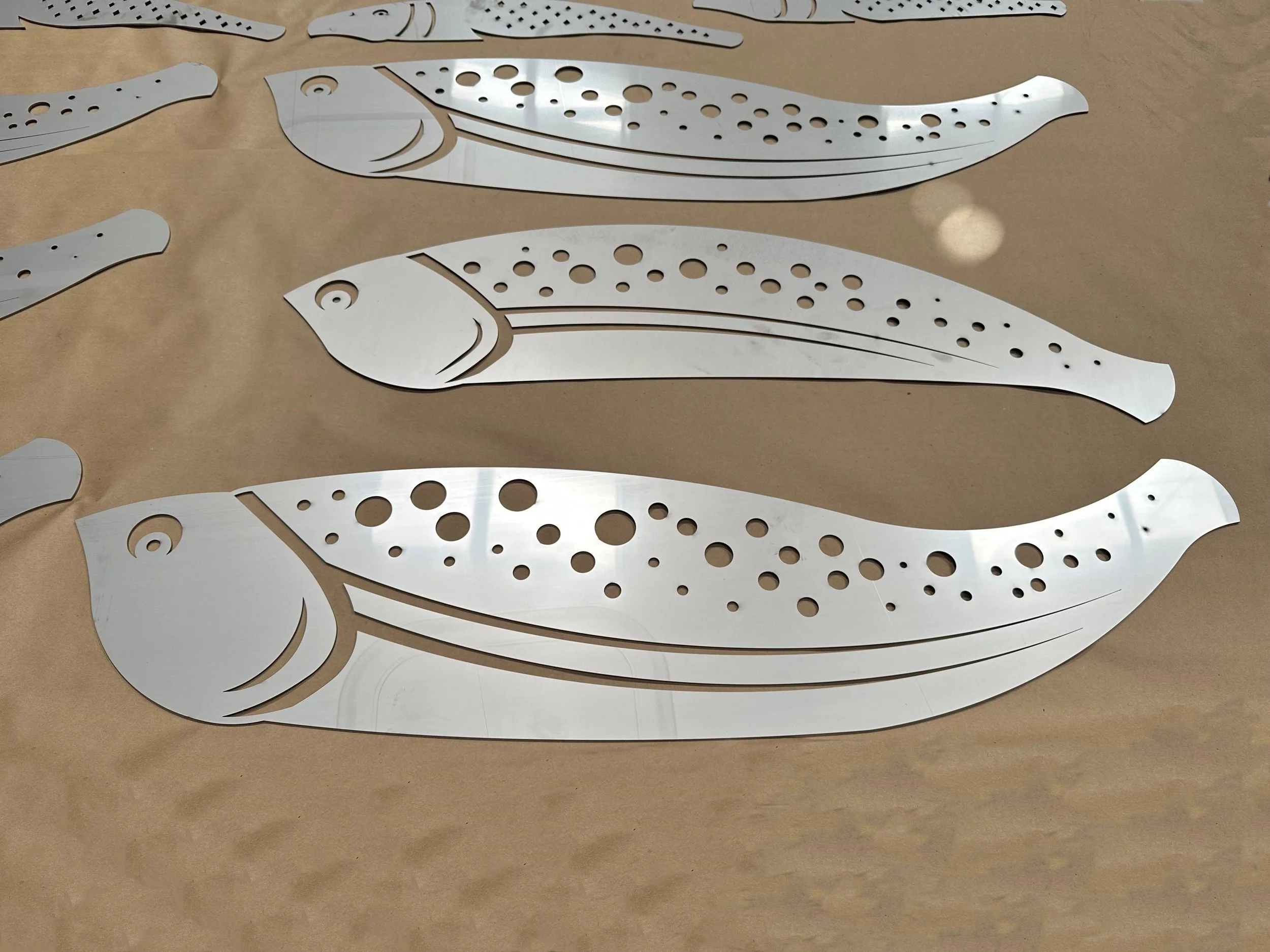

Laser Cutting

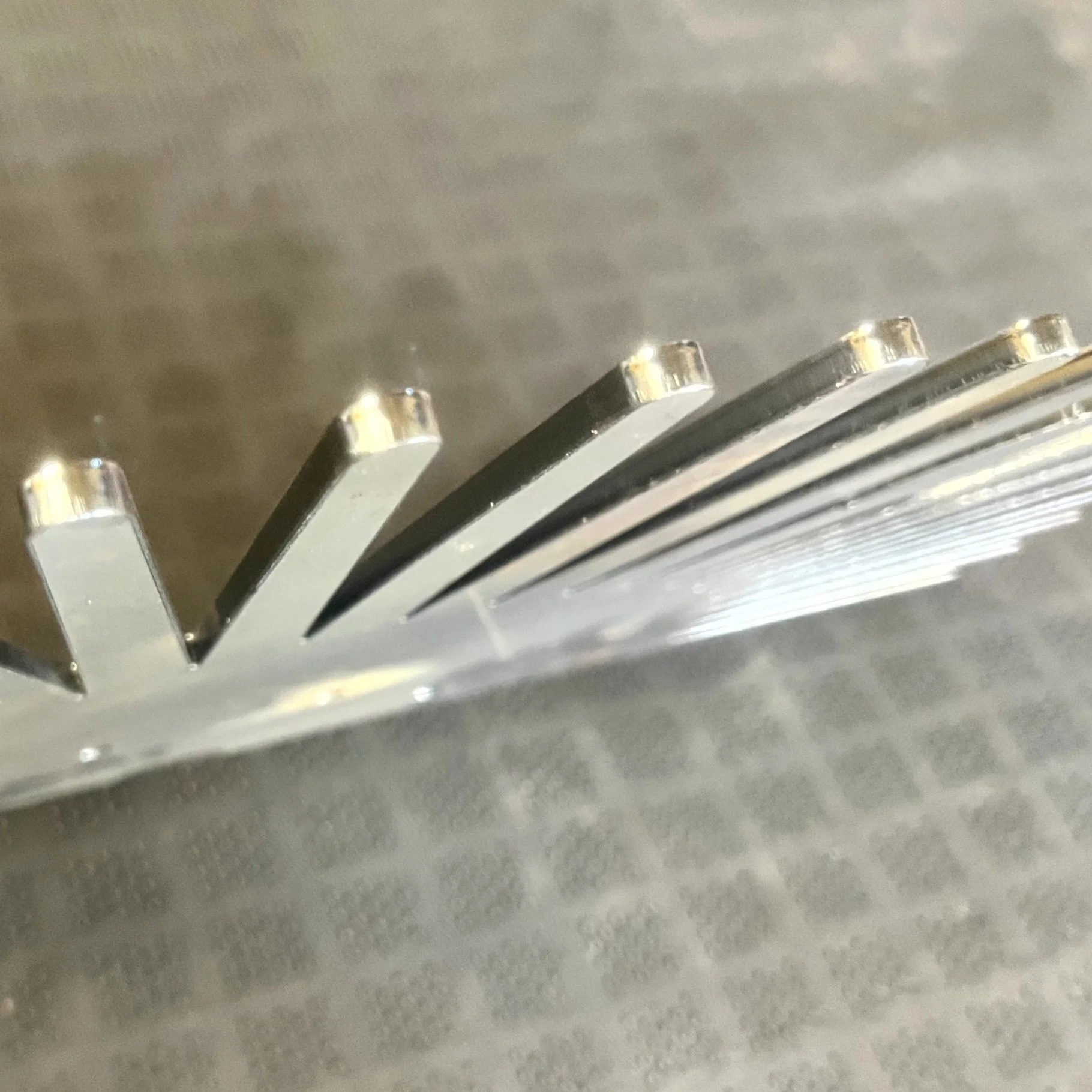

Our ability to cut up to 1” thick materials on 5’ x 10’ sheets with high accuracy makes us the perfect partner for all of your laser cut part needs. We offer a 24 hour turnaround on most parts.

-

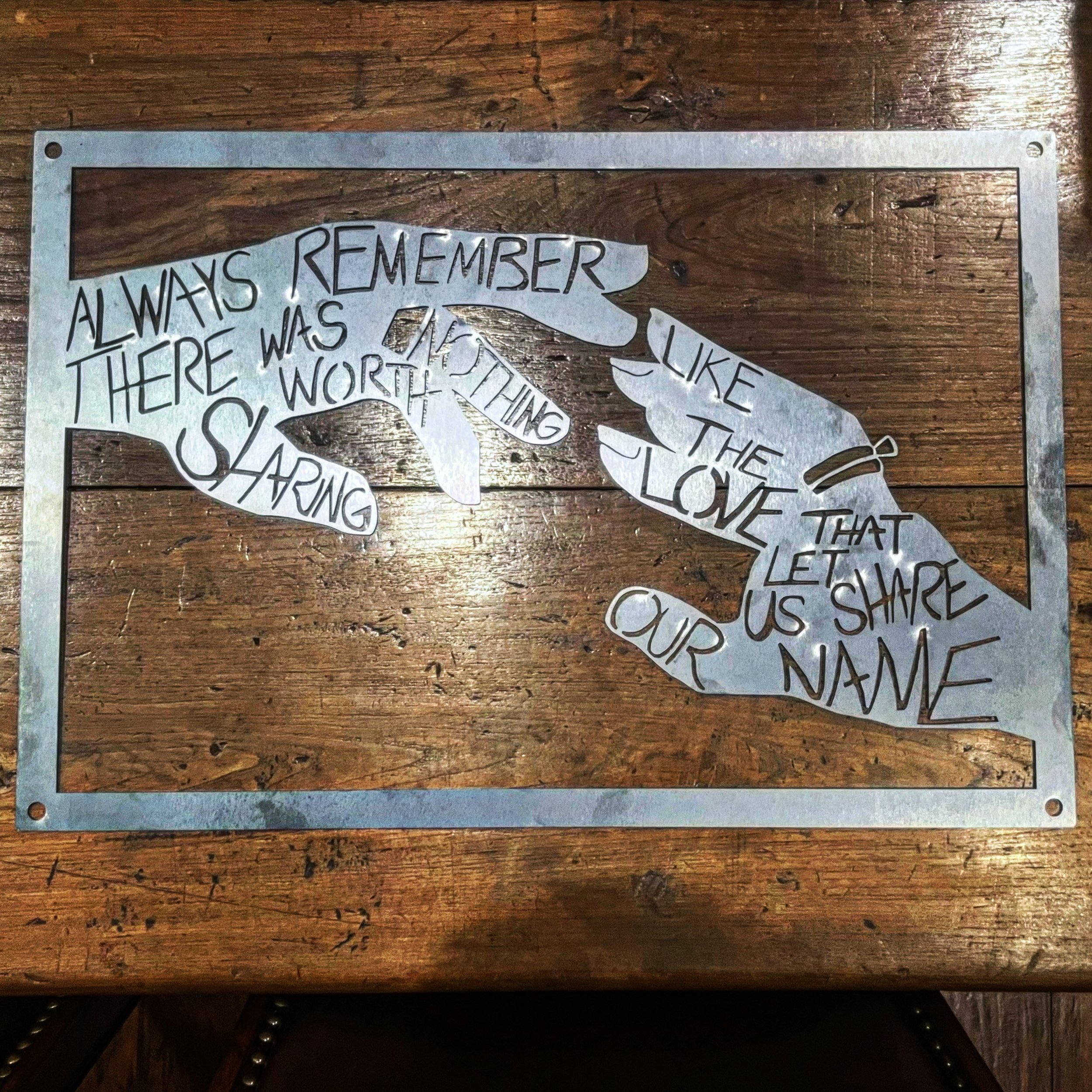

Laser Etching

Whether it be names, cross marks, part numbers, or signatures, our etching services are available to help customize your order.

-

CUSTOM QUOTES AND DESIGN

If you know what you want but are not sure how to make it a reality, let us help! We can help you design your parts and get them cut to your exact specifications.

Materials

-

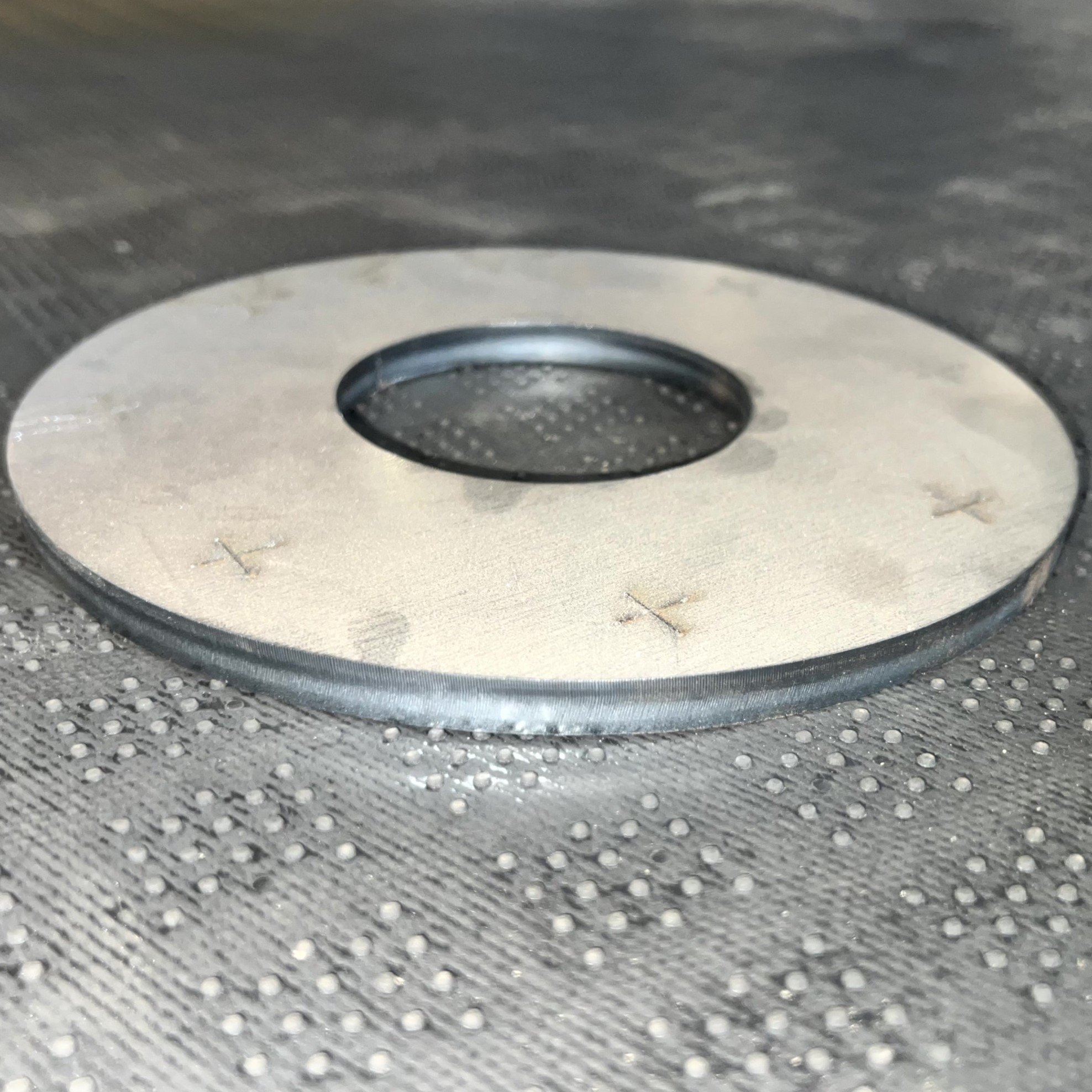

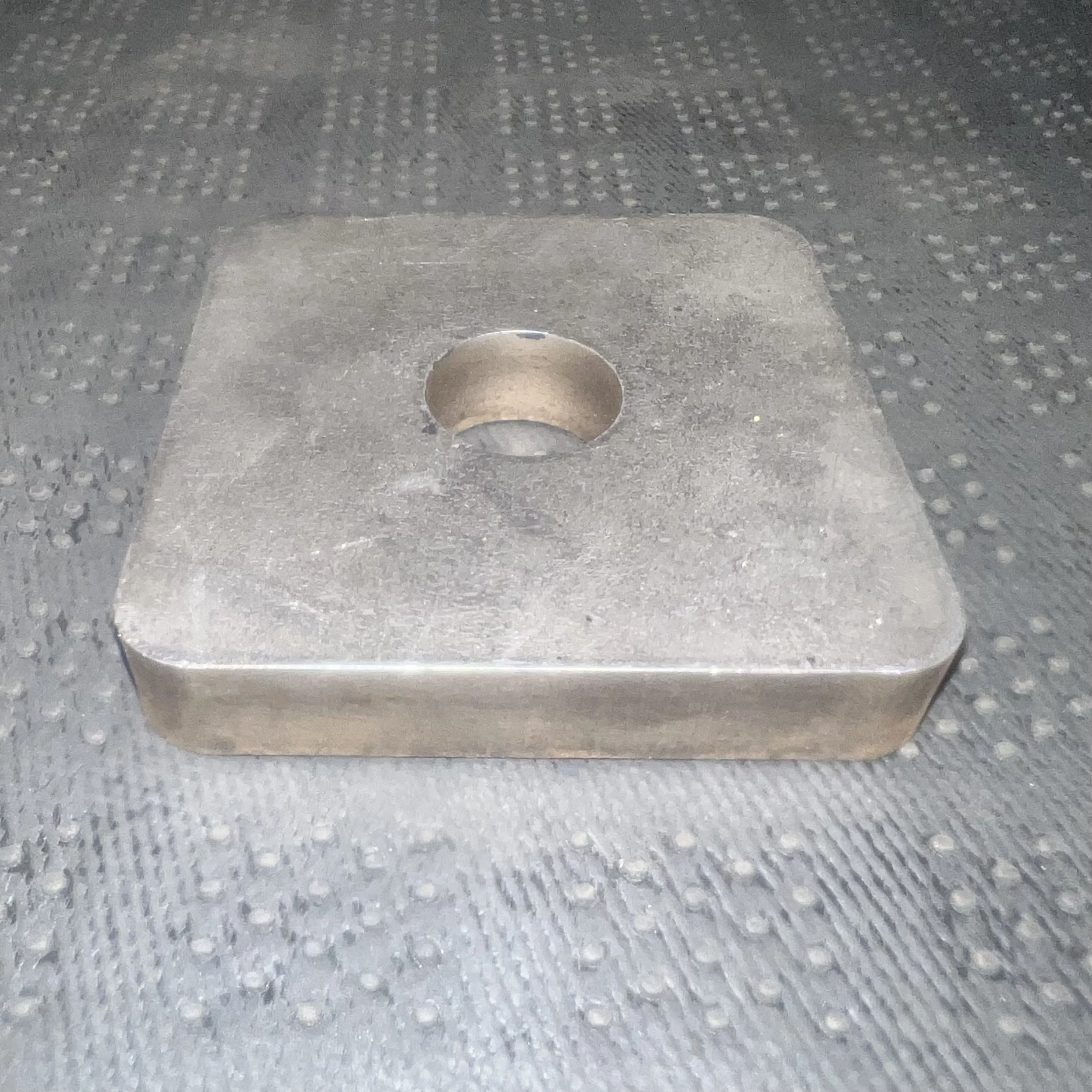

Mild steel is the workhorse of most industries, even with our own parts. We offer cutting from 0.036" up to 1.00" with various options for cutting style.

-

With high durability and strength, stainless steel is another common option. We offer cutting from 0.036" up to 1.00".

-

Aluminum is known for its lightweight, high strength to weight ratio and corrosion resistance. We offer cutting from 0.040" up to 0.750".

-

Copper has excellent strength and hardness properties, in addition to its thermal conductivity. We offer cutting from 0.040" up to 0.630"..

-

With high strength, hardness, and aesthetic appeal, Brass can be a great option. We offer cutting from 0.040" up to 0.375".

Cutting

assist

gases

-

High-pressure air is an increasingly popular assist gas for fiber laser cutting due to its cost-effectiveness and versatility. Made up primarily of nitrogen and oxygen, it offers a balance between speed and cut quality, making it suitable for a wide range of materials including mild steel, stainless steel, and aluminum. Air is significantly cheaper than pure nitrogen or oxygen and eliminates the need for separate gas supplies. However, it can produce more burrs and edge oxidation than nitrogen, particularly on thicker or highly reflective materials, and may require more post-processing depending on the quality requirements of the final part. Can be used on up to 0.25” mild steel, 1” stainless steel, and 0.75” aluminum.

-

Using oxygen as an assist gas in fiber laser cutting offers several advantages, particularly for cutting mild steel. Oxygen promotes an exothermic reaction with the metal, which enhances cutting speed and allows for greater thicknesses to be processed with lower laser power.

-

Nitrogen is commonly used as an assist gas in fiber laser cutting when clean, oxide-free edges are a priority, such as in stainless steel or aluminum processing. As an inert gas, nitrogen prevents oxidation during cutting, resulting in smooth, high-quality edges that often require little to no post-processing. However, nitrogen does not contribute additional heat to the cutting process, which can lead to slower cutting speeds and higher gas consumption, especially on thicker materials. This makes it less cost effective and efficient for some applications compared to oxygen.